November 23: Coal is the main source of energy used in brick kilns. Nepal used to import coal from India before the southern neighbor banned its export. Currently, coal is imported from the United States of America and Indonesia at rates as high as 300 percent compared to that of India. This has caused a big problem to brick kilns.

A total of 85 brick kilns of Province 1 have not been able to bake the raw bricks due to the shortage of coal.

The president of Province 1 chapter of the Confederation of Nepalese Industries, Bhim Ghimire who is also the coordinator of AB Bricks and Tiles Industry, said that bricks could not be produced for two years due to the Covid-19 pandemic and that the price of bricks would be higher due to increase in cost of coal and labor charge. According to him, it is more likely for the prices of bricks to reach Rs 25 per piece from Rs 23 per piece.

The price of No.1 brick was only Rs 18 per piece two years ago. The price of brick has increased by Rs 7 per piece in just the interval of 3 years.

The price of coal, which was available for US$ 96 per ton two years ago, increased by three folds to US$ 280 per ton. It costs Rs 40,000 to 42,000 per ton in Nepal. However, the brick kilns are facing a shortage of coal as it takes at least six months for the coal to arrive in Nepal via ship from the United States and Indonesia.

Ramesh Bhagat, operator of ACC Brick Industry, informed that the availability of coal has begun to increase alongside the decline in the prices. The price of coal which used to cost US$ 280 per ton has now dropped to US$ 240, he said. Until two years ago, coal used to be bought and sold at US$ 95 per ton in the international market.

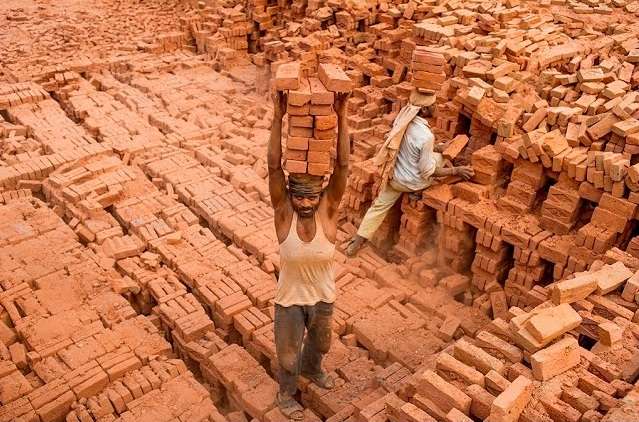

Due to the Covid-19 pandemic, the brick industry of Nepal could not produce new bricks for the last two years because the workers coming from West Bengal of India could not arrive in Nepal. Although some of the few industries produced bricks with the help of indigenous workers, they could not sustain the business.

The price of bricks which was Rs 18 per piece before the Covid-19 pandemic reached to Rs 23 per piece after the brick industries started to close down. This time as well, due to the increase in the price of coal and the labor cost of Indian workers, new bricks can be sent to the market only at Rs 25 per piece, said Bhagat.

Bhagat says, “Even now, the production price of bricks reaches up to Rs 28 per piece. But to maintain the balance in the market, it will be sold at Rs 25 per piece this time as per the policy of increasing prices gradually without increasing it all at once.”

Before the lockdown, 85 brick factories in Province 1 had been producing bricks worth Rs 3.40 billion annually. Industrialists said that if the supply of coal eases this year, bricks would be produced in the same proportion. This time the workers have already arrived in September because they had already received the money in August at their residence in Kuch Vihar, West Bengal, India. In Province 1, around 22,000 workers come from Kuch Vihar every year. This year the number of workers has reached 25,000.

Province 1 has been producing 350 million bricks annually. From this, the industrialists have been paying revenue of Rs 350 million to the government. Mahendra Shah, the president of the Brick Producers Association Morang, said that the prices had gone up last year after an interval of six years.

Rajan Timsina, the general secretary of the Koshi Brick Industry Entrepreneurs Association said it would take six months for the coal to arrive in Nepal from the United States and Indonesia. He said that the brick industry is not in a position to produce at full capacity right now due to the delay in transportation of coal by ships, delay in coal production and other lengthy processes.